Overview

Temperature sensing matters. It affects safety, product quality and energy use. Choosing the right sensor saves time and money. This guide compares three common sensor types: thermistors, thermocouples and thermopiles.

We use simple language. We include charts and recent 2025 data. Focusensing (Hefei, China) makes and customizes these sensors for B2B customers.

Quick Definitions

- Thermistor: A temperature-sensitive resistor. Comes in NTC (resistance drops with heat) and PTC (resistance rises with heat). Contact measurement.

- Thermocouple: Two dissimilar metals joined to make a voltage that depends on temperature difference. Contact measurement. Wide range and robust.

- Thermopile: An array of thermocouples that measure infrared radiation for non-contact temperature sensing. MEMS thermopiles are compact and mass-producible.

Core Differences: Table Snapshot

| Feature | Thermistor | Thermocouple | Thermopile (MEMS) |

|---|---|---|---|

| Measurement type | Absolute (contact) | Relative (contact) | Relative (non-contact IR) |

| Typical range (°C) | -55 to 150 | -200 to 1600 | Room temp range; depends on target emissivity |

| Typical accuracy | ±0.1–0.5 °C | ±1–2 °C | ±0.5–2 °C (array dependent) |

| Typical response | <1 s | 0.2–1 s | 10–200 ms |

| Durability | Moderate | High (harsh conditions) | Compact; sensitive to optics |

| Common uses | HVAC, medical probes, batteries | Furnaces, engines, industrial | Non-contact screening, thermal imaging |

Charts to Help Compare

Tip: Replace the image paths below with your hosted images if needed. The charts included here are created from 2024–2025 industry figures to give context.

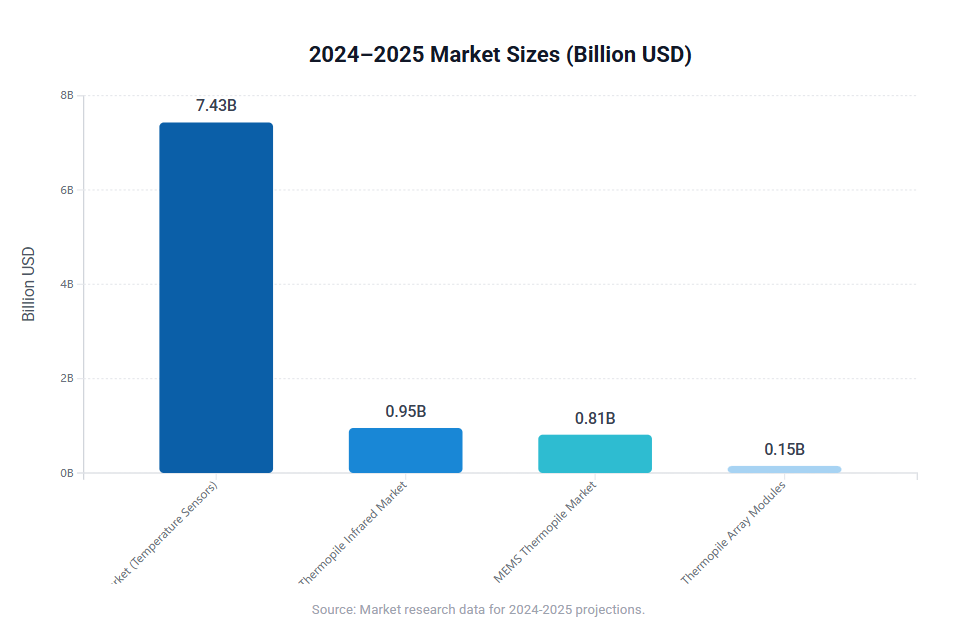

2024–2025 Market Sizes (Billion USD)

Figure: Relative market size for general temperature sensors and thermopile/IR markets. (Sources: industry market reports 2024–2025)

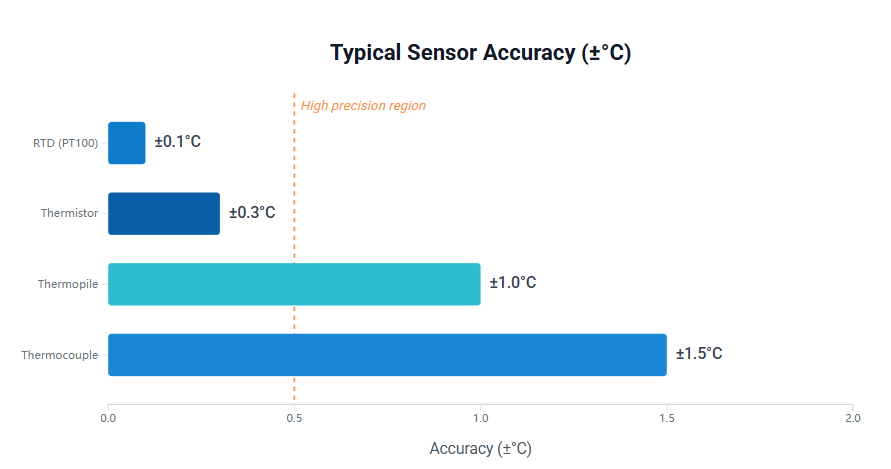

Typical Sensor Accuracy (±°C)

Figure: Thermistors and RTDs deliver the best accuracy for close-range measurements. Thermocouples trade some accuracy for range and durability.

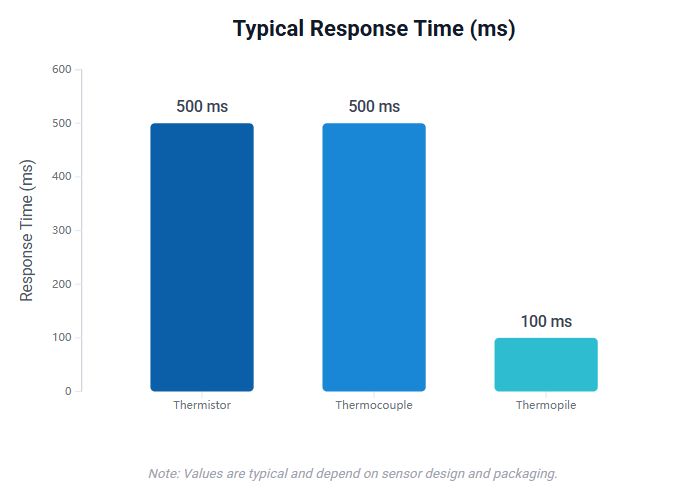

Typical Response Time (ms)

Figure: Thermistors and thermocouples are very quick. Thermopiles measure infrared and often operate in tens to hundreds of milliseconds.

When to Use a Thermistor

Choose a thermistor when you need precision at low to mid temperatures. They are compact and cost-effective.

- Best for: Medical probes, battery management, HVAC control, consumer electronics.

- Range example: -55°C to 150°C.

- Precision example: ±0.2°C for high-grade NTC sensors from Focusensing.

- Why pick it: High sensitivity and fast response for close contact measurements.

When to Use a Thermocouple

Thermocouples are the go-to for high temperatures and harsh conditions.

- Best for: Furnaces, kilns, engine exhaust, industrial ovens.

- Range example: -200°C to 1600°C (depends on type: K, J, T, etc.).

- Durability: High. Works well under vibration, shock and high heat.

- Why pick it: Wide range and robustness. Low cost for many industrial uses.

When to Use a Thermopile (MEMS)

Thermopiles are ideal when you need non-contact infrared measurements or a compact thermal array.

- Best for: Fever screening, non-contact body temp, simple thermal imaging and IoT devices.

- Array use: Multiple thermopile channels can create low-resolution thermal maps.

- Why pick it: Measure without touching, useful for moving or sensitive targets.

Engineering Selection Checklist

Follow this short checklist before you buy or design:

- Define the required temperature range.

- Set the accuracy and resolution needs (±0.1°C? ±1°C?).

- Decide on contact vs non-contact.

- Assess the environment (vibration, moisture, chemicals).

- Plan for response time and data sampling rates.

- Factor in cost, calibration and maintenance.

2025 Trends & Market Signals

Recent market studies and industry reports show steady growth in temperature sensors in 2025. Key trends:

- MEMS thermopiles are gaining traction for compact IR solutions and low-cost thermal imaging modules.

- IoT integration is driving demand for digital sensor outputs and small, calibrated modules.

- Energy efficiency pushes better thermal control in HVAC, EVs and industrial systems.

- Customization remains critical: B2B customers want custom resistance values, probe lengths, and calibration curves.

Focusensing is active in these areas. The company offers custom thermistors, RTDs and thermocouple probes and supports digital sensor integration for IoT systems.

Real-World Case Studies

1. EV Battery Pack Thermal Management

Problem: Cells heat unevenly during charge/discharge. Solution: Focusensing NTC probes at cell level (±0.2°C), RTDs at module level. Result: Improved thermal control and longer battery life.

2. Industrial Kiln Monitoring

Problem: Need to monitor furnace over 1000°C. Solution: Type K thermocouples with protective sheath. Result: Reliable, low-maintenance operation.

3. Non-Contact Fever Screening

Problem: Fast, safe screening at high throughput locations. Solution: MEMS thermopile module with 1–4 channels, environmental compensation and calibration. Result: Rapid detection with minimal false positives.

Focusensing — What We Offer

Focusensing is a China-based manufacturer focused on B2B temperature sensor supply. Core offerings:

- NTC & PTC thermistors — standard and high-precision grades.

- RTD sensors — PT100 and PT1000 options with high stability.

- Thermocouple probes — custom sheath, junction and extension wiring.

- Digital sensors — I²C/SPI ready modules for IoT integration.

- Full customization — resistance, thread size, length, calibration.

Contact Focusensing for samples or customized quotes. Visit: www.focusensing.com

Downloadable Assets & Image Notes

Included charts for this article were generated to illustrate 2024–2025 trends and comparisons. If you publish this page, host the images on your CDN and update the <img src="..."> paths.

- market_sizes_2025.png — Market size comparison (temperature sensors vs thermopile IR market).

- accuracy_comparison_2025.png — Typical accuracy across sensor types.

- response_time_2025.png — Typical response times in ms.

If you need these images in your brand colors, we can re-export them. Ask Focusensing for branded charts and web-ready assets.

References & Sources

Selected sources used to prepare this page: Focusensing product pages and company info, industry market reports (2024–2025), technical summaries on thermocouples and MEMS thermopiles. Replace or expand the citations for your final publication if you require direct links to each report.

+86-551-69109668

+86-551-69109668